Users can easily program nodes for continuous, periodic burst, or event-triggered sampling with the SensorConnect software. The optional web-based SensorCloud interface optimizes data aggregation, analysis, presentation, and alerts for gigabytes of sensor data from remote networks. Our open-source, comprehensive communications and command library (API) allows you to easily incorporate the product into third party platforms.

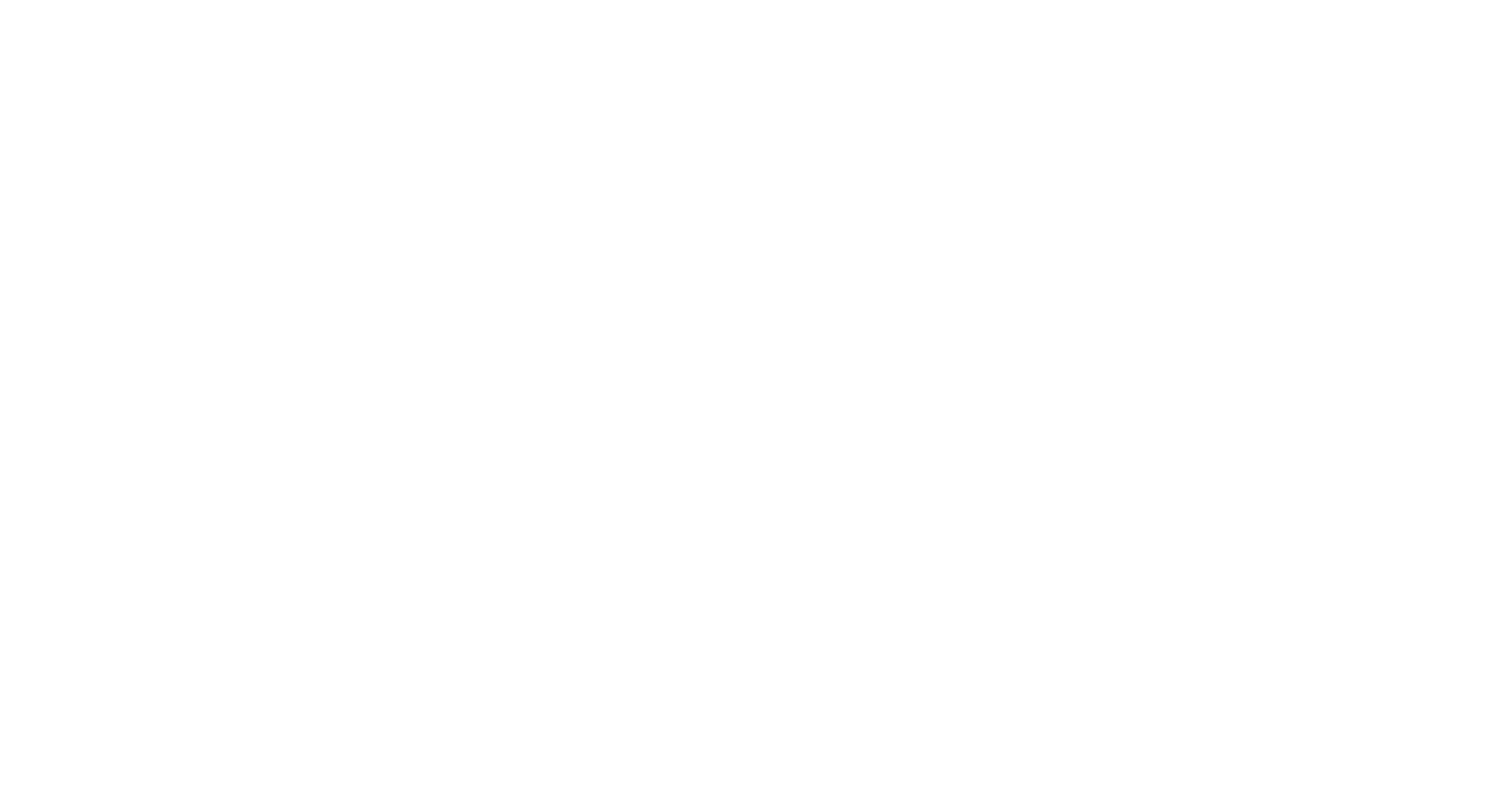

“This end-to-end wireless sensing solution reduces development and deployment time, making it ideal for test and measurement, condition-based monitoring, health monitoring of rotating components, aircraft structures and vehicles, vibration monitoring, and vehicle dynamics testing,” said Bessette.

Features and benefits of the G-Link-200-40G include:

- Versatile Operating modes

- Continuous, periodic burst, and event-triggered sampling

- Output acceleration or derived vibration parameters; VelocityRMS (IPS), AccelerationRMS, AccelerationPk-Pk, and Crest Factor (APk/ARMS)

- LXRS protocol allows lossless data collection, scalable networks, and node synchronization of ±50 μs

- High performance sensing

- +/- 10, 20, or 40 g measurement range

- High-resolution data with 20-bit A/D convertor

- Extremely low noise on all axis 80 μg/√Hz

- User-configurable low-pass and high-pass filters

- Wireless range up to 2 km (800 meters is typical)

- On-board temperature sensor (+/- 0.1 °C)

- Ruggedized packaging

- -40 °C to 85 °C operating temperature range

- IP67 rating

- Three user-replaceable high capacity ½ AA 3.6V Lithium batteries (13.0Wh)

- FCC\IC, CE certifications

- Ease of use

- Scalable networks for easy expansion, remote configuration, acquisition, and display of data with SensorConnect

- Easy custom integration with open-source, comprehensive communications and command library (API). The MicroStrain Communication Library makes it simple to write code to interact with our wireless sensors

- Optional web-based SensorCloud platform, which optimizes data storage, viewing, alerts and analysis. Use SensorCloud with MathEngine analytics tool provides characterization metrics between machines and operating environments through the equipment life-cycle

Click here for more information and to order now!

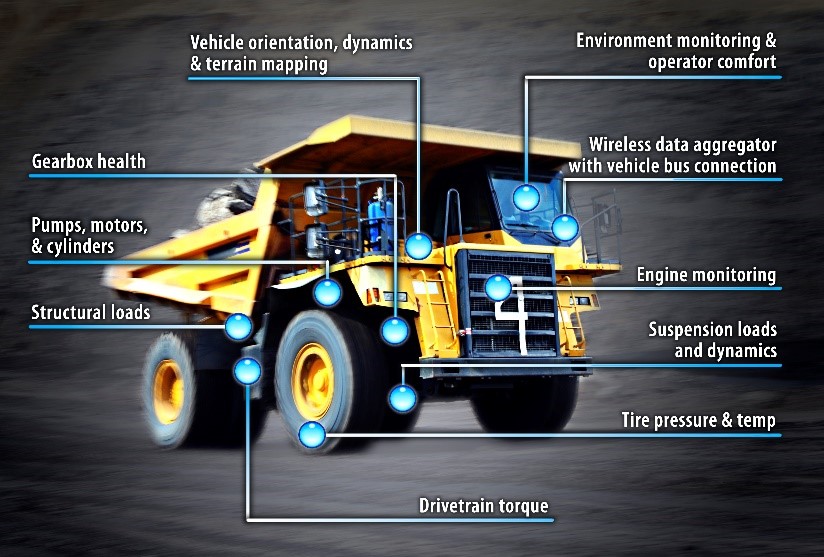

The G-Link-200-40G ruggedized high-speed triaxial acceleromter node has a +/- 10, 20, 40 g measurement range that allows high-resolution data acquisition at noise levels as low as 80 μg/√Hz

Measuring machine structural and componenet fatigue in a high-vibration environment is necessary to pevent breakdowns and improve design.

Measuring in-use vibration of factory equipment allows predictive maintenance in high-value production processes.

Prior to launch, the G-Link-200 underwent (and succeeded in) rigorous field testing, including cold weather exposure, electrostatic discharge, ingress protection, and HALT (Highly Accelerated Life Test).

We are pleased to announce the launch of the new 40g version of our G-Link-200 ruggedized high-speed triaxial accelerometer node. Ideal for real-time data acquisition and machine health monitoring of high-value assets, the G-Link-200 measures motion, vibration, acceleration/deceleration, tilt, and impact events.

We are pleased to announce the launch of the new 40g version of our G-Link-200 ruggedized high-speed triaxial accelerometer node. Ideal for real-time data acquisition and machine health monitoring of high-value assets, the G-Link-200 measures motion, vibration, acceleration/deceleration, tilt, and impact events.