Author:

Publication:

- MicroManufacturing

Looking ahead, experts see more unmanned aerial vehicles taking to the skies to carry out a variety of military and non-military missions. It’s a prospect that should cheer micromanufacturing firms, which make many key components that assist today’s UAVs in flight and help them handle their challenging missions....

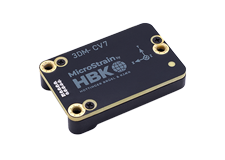

MEMS devices stowed aboard UAVs can also be used to perform sensor functions. Tiny MEMS sensors can be integrated into larger systems that are still very compact themselves, making them suitable for small flying machines. For example, the 3DM-GX3-25 from MicroStrain Inc., Williston, Vt., is a miniature attitude-heading reference system featuring MEMS sensors. One version of the device combines an accelerometer, a gyro, a magnetometer, temperature sensors and an onboard processor in a package measuring only 38mm × 24mm × 12mm and weighing just 11.5g. This unit, which is roughly a quarter the size of its predecessor, is one result of the continued push to reduce the size, weight and power consumption of UAV components.

A related trend is the integration of multiple UAV instruments to boost functionality as much as possible in a single system, according to Dave Churchill, MicroStrain’s vice president of engineering for inertial technology. Churchill pointed out that such instrument integration can eliminate some of the enclosures, connectors and cabling needed by UAV systems, significantly reducing their size, weight and cost.

To read the article in its entirety, click here.