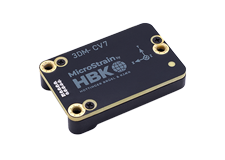

The 3DM-GX3® -15 is a high-performance, miniature Inertial Measurement Unit and Vertical Gyro, utilizing MEMS sensor technology. It combines a triaxial accelerometer, triaxial gyro, temperature sensors, and an on-board processor running a sophisticated sensor fusion algorithm to provide static and dynamic orientation, and inertial measurements.

Datasheet Manual

Best in Class

- precise inertial measurements

- high-speed sample rate & flexible data outputs

- high performance under vibration and high g

Easiest to Use

- smallest, lightest industrial IMU available

- simple integration supported by SDK and comprehensive API

Cost Effective

- reduced cost and rapid time to market for customer’s applications

- aggressive volume discount schedule

IMU Specifications

|

Attitude and Heading |

|

|

Attitude heading range |

360° about all 3 axes |

|

Accelerometer range |

±5 g standard |

|

Gyroscope range |

±300°/sec standard |

|

Static accuracy |

±0.5° pitch and roll typical for static test conditions |

|

Dynamic accuracy |

±2.0° pitch and roll for dynamic (cyclic) test conditions and for arbitrary angles |

|

Long term drift |

pitch and roll drift eliminated by complementary filter architecture |

|

Repeatability |

0.2° |

|

Resolution |

<0.1° |

|

Data output rate |

up to 1000 Hz |

|

Filtering |

sensors sampled at 30 kHz, digitally filtered (user adjustable ) and scaled into physical units; coning and sculling integrals computed at 1 kHz |

|

Output modes |

acceleration, angular rate, deltaTheta, deltaVelocity, Euler angles, quaternion, rotation matrix |

| General | |

|

A/D resolution |

16 bits SAR oversampled to 17 bits |

|

Interface options |

USB 2.0 or RS232 |

|

Baud rate |

115,200 bps to 921,600 bps |

|

Power supply voltage |

+3.2 to +16 volts DC |

|

Power consumption |

80 mA @ 5 volts with USB |

|

Connector |

micro-DB9 |

|

Operating temperature |

-40° C to +70° C |

|

Dimensions |

44 mm x 24 mm x 11 mm - excluding mounting tabs, width across tabs 37 mm |

|

Weight |

18 grams |

|

ROHS |

compliant |

|

Shock limit |

500 g |

|

Software utility |

CD in starter kit (XP/Vista/Win7/Win8 compatible) |

|

Software development kit (SDK) |

complete data communications protocol and sample code |

Sensor Specifications

|

Accels |

Gyros |

|

|

Measurement range |

±5 g |

±300°/sec |

|

Non-linearity |

±0.1 % fs |

±0.03 % fs |

|

In-run bias stability |

±0.04 mg |

18°/hr |

|

Initial bias error |

±0.002 g |

±0.25°/sec |

|

Scale factor stability |

±0.05 % |

±0.05 % |

|

Noise density |

80 µg/√Hz |

0.03°/sec/√Hz |

|

Alignment error |

±0.05° |

±0.05° |

|

User adjustable bandwidth |

225 Hz max |

440 Hz max |

|

Sampling rate |

30 kHz |

30 kHz |

|

Options |

||

|

Accelerometer range |

±1.7 g, ±16 g, ±50 g |

|

|

Gyroscope range |

±50°/sec, ±600°/sec, ±1200°/sec |

|

General Documentation

- 3DM-GX3® -15 Datasheet

- 3DM-GX3® -15 Quick Start Guide

- 3DM-GX3® -15,-25 MIP Data Communications Protocol

- 3DM-GX3® Data Communications Protocol Errata

- 3DM-GX3® -15 Declaration of Conformity

Technical Notes

- Extending the USB Cable

- Using an Hardware Datalogger with Inertial Sensors

- 3DM-GX3® Startup Settings

- Using Dataloggers with Inertial Sensors

- Phihong PSA05R-090 Power Supply

- 3DM-GX3® -15 Communication and Power Connector

Mechanical Prints

- 3DM-GX3® -15 STP file

- 3DM-GX3® -15 Mounting Diagram

- 6212-1000 4005-0037 Micro D-to-RS232 Communication and Power Cable

- 6224-0100 Craft Cable with Micro DB9 and 9 flying leads

- 6212-1040 9022-0019 Micro D-to-USB Communication and Power Cable

Firmware Upgrade

Software Download

Software Development Kit

Using MIP Monitor software, to reset the device to the factory defaults:

- Establish communication as normal with the sensor.

- Click Settings.

- Click Load Default Settings and a message box pops up.

- Click OK and the message box disappears.

- Click Settings again.

- Click Save Current Settings and a message box pops up.

- Click OK and the message box disappears.

This process does not erase any hard and soft iron calibration that may be on the device.

The Hard and Soft Iron Cal software we provide must be used to do that.

The main difference between single byte (SB) and MIP is as follows:

- All MIP commands and data have a header and checksum. SB only has a header (the echo of the command byte) and a checksum on the replies. This means that the programmer has to create a header and calculate the checksum for a command before s/he sends the command. This was not necessary with SB.

- MIP setup and control commands (like start and stop continuous mode) send an ACK/NACK field with a reply. SB does not. The ACK/NACK field has an error code that can be used to confirm that a command was accepted.

- MIP packets can contain multiple command and data fields. SB commands and data only have one fixed field.

The reason we created MIP was the higher reliability for communications and control, plus the ability to have custom data messages. SB was prone to phantom commands in a noisy environment. In addition, SB had a limited number of data combinations available.

To move code from Single Byte to MIP with simple applications is fairly painless if you follow some guidelines.

- You can “prebuild” all your setup and control commands and make them constants in your code. You can plug the prebuilt packet constants into the same part of the code that you previously used to send a single byte command (In essence, you are sending a “multi-byte” command instead of a single byte command). We have a “packet builder” tool in the MIP Monitor that will build the packet for you. You can try out the command and then copy the packet and paste it directly into your code as a string constant.

- When you design the MIP data message, make sure all the “data rate decimation” values are the same. This will make all the data packets identical, which makes finding data in the packet similar to finding data in a SB data message (by using fixed offsets).

The ECCN is 7A994.

From time to time, MicroStrain releases firmware upgrades for its 3DM-GX3® inertial sensors. These firmware upgrades represent operating improvements, new functions, etc. In most cases, the user may download these upgrades and perform the upgrade using a simple step-by-step process. This technical note describes which firmware upgrades may be accomplished by the user and which firmware upgrades must be done at the factory. Familiarity with 3DM-GX3® operation is assumed. The upgrade procedure employs a Microsoft Windows computer and the Microsoft HyperTerminal utility.

Many inertial applications incorporate dataloggers. The datalogger can take many forms: hardware or software, analog or digital, simple or complex, and/or combinations of all. For our purposes, let’s work through a simple-digital-software datalogger. In this case, datalogger software is installed on a computer. The inertial sensor is connected to the computer via an RS-232 communication interface. The inertial sensor is pre-programmed to automatically send data when powered. The computer receives the stream of data and the datalogger software continuously records the stream to a data file.

The LORD MicroStrain 3DM-GX3 inertial sensor family allows the user to pre-program the inertial sensor so that it continuously outputs specific data packets at specific sampling rates each time it is powered on. This functionality facilitates integration of the inertial sensor with other equipment and systems. For example, connection of the 3DM-GX3 inertial sensor to a datalogger becomes quite easy. The user pre-programs the 3DM-GX3 data output settings on his desktop, connects the 3DM-GX3® to the datalogger’s RS-232 port, powers the 3DM-GX3, and the datalogger records the inertial data. This technical note assumes some familiarity with your particular 3DM-GX3 inertial sensor and its accompanying MIP Monitor (Windows-based) software.

|

Static accuracy |

±0.5° pitch, roll, heading typical for static test conditions |

|

Dynamic accuracy |

±2.0° pitch, roll, heading for dynamic (cyclic) test conditions and for arbitrary angles |

Important note: Unlike the -25, the -15 does not contain magnetometers. Magnetometers measure Earth's magnetic fields and provide the AHRS with a reference to produce an accurate heading. In the -15, the heading is accurate from moment to moment but drifts over time and should not be relied upon.

Here is a link to a detailed technical note: http://files.microstrain.com/Orientation%20Conversion%20formulas.pdf

Yes. We have had good success with several types of off-the-shelf USB to serial port adaptors, such as those from IOGear and Keyspan, which may be purchased through any of the electronics products distributors.

No – only one can be used at a time. The device auto-senses which communication signal is attached (USB or serial), and only uses that channel for communications.

The standard unit uses a specialized Ulti-Mate brand micro-DB9. This technical note contains more details: http://files.microstrain.com/TN-I0023_Inertia-Link_3DM-GX2_3DM-GX3_Pin-Outs.pdf

The OEM unit uses a Samtec FTSH-105-01-F-D-K. This technical note contains more details: http://files.microstrain.com/3DM-GX3-25_OEM_Footprint_and_Connector.pdf

LORD MicroStrain® suggests that you purchase additional connectors with your order.

The 3DM-GX3 USB and RS-232 communication interfaces are built to satisfy the standard USB-IF and EIA specifications. LORD MicroStrain® provides 6 foot cables as standard. Many techniques can be used to extend the length of the communication interfaces including powered USB hubs, USB boosters, RS-232 extenders, etc.

The 3DM-GX3 standard enclosure has been designed with precision alignment holes on the ‘ears’ of the enclosure to allow the user to install the unit with precise alignment to the rest of the components in the user’s application.

The 3DM-GX3 is calibrated at the factory. The user is also provided with Hard and Soft Iron Calibration software to field calibrate the GX3 in situ. This video further describes the function: http://www.microstrain.com/video/hard-soft-iron-calibration

Important note: Hard and soft iron calibration is not required for the 3DM-GX3-15 and the 3DM-GX315 OEM. These units do not contain magnetometers.

From time to time the 3DM-GX3 may need recalibration. For example, as a result of coming in contact with magnetic influences (magnets, motors, etc.), residual magnetism may be picked up by the on-board components which will alter the calibration. Another example: the 3DM-GX3 receives a severe shock, slightly altering the position of the circuit boards in relation to the enclosure, again altering the calibration. In these cases the unit should be returned to the factory for recalibration.

Yes. Any number of units can be operated by a host at the same time. Several considerations surround this implementation (primarily computing power) and we suggest that you discuss your requirements with LORD MicroStrain® sales or a support engineer.

For the standard units, here is a link to a detailed technical note: http://files.microstrain.com/TN-I0023_Inertia-Link_3DM-GX2_3DM-GX3_Pin-Outs.pdf

For the OEM units, here is a link to a detailed technical note: http://files.microstrain.com/3DM-GX3-25_OEM_Footprint_and_Connector.pdf

Yes, there are no limitations. However, if a user requires a ‘zeroing’ of the axes, this must be done in the user’s external application. Good practice dictates that the orientation matrix be used to calculate such zeroing. Please also be aware of the mathematical singularity in Euler angles.

The user should be aware that the Euler angle formulation in general contains a mathematical singularity at Pitch = +90 or –90 degrees. In practice, poor numerical results will be present if the Pitch angle exceeds +/-70 degrees. In applications where the Pitch angle cannot be guaranteed to exceed these values, it is recommended that the orientation matrix output be utilized instead.

Yes. The sampling rates are user adjustable.

For the -15 and -25, the user may set the sampling rate at up to 1000 Hz depending on the data quantity.

For the -35, the user may set the AHRS sampling rate up to 1000 Hz depending on the data quantity and the GPS sampling rate up to 4 Hz.

For the -45, the user may set the Navigation sampling rate up to 100 Hz.

The baud rate is user adjustable and may be set to 9600, 19200, 115200 (default), 230400, 460800, and 921600.

Yes. The presence of strong magnetic fields or large magnetic materials will distort Earth’s weak local magnetic field and this will influence the on-board magnetometers. A hard and soft iron calibration software utility is provided to field calibrate the 3DM-GX3-25, 3DM-GX3-25 OEM, 3DM-GX3-35 and 3DM-GX3-45.

The 3DM-GX3-15 and 3DM-GX3-15 OEM do not contain magnetometers and are not affected by hard and/or soft iron interference.

The following orientation outputs formats are available:

- Acceleration

- Angular Rate

- Magnetic Vector

- DeltaAngle and DeltaVelocity

- Orientation Matrix

- Quaternion

- Euler Angles (pitch, roll and yaw)

- ...and more.

A detailed description of these outputs can be found in the Data Communications Protocol manual of each product.

The standard units support both USB and RS-232 interface.

The OEM units support both USB and TTL.

Yes. We provide a complete data communications protocol manual which describes in detail each and every command and response that is available with the device. Applications may be developed in any programming environment (C, VB, LabVIEW, Linux, Matlab, etc.) which supports serial communication.

We provide a general application for Microsoft XP/Vista/Win 7 operating systems that configures, reads, displays and saves data generated by the device. This application (MIP Monitor) supports both the USB and RS-232 communication interfaces.

When you initially purchase a 3DM-GX3, a starter kit (SK) provides you with everything you need to get started! SKs include a 3DM-GX3 module, communication and power cables, software, manuals and GPS antenna if applicable. In subsequent purchases you may only require additional modules or other individual components. Several communication interfaces are available creating several starter kit variations.

No. There is no upgrade path.