Industrial/off-highway vehicles are often subject to ongoing stresses and wear, as well as challenging navigation over rough terrain that can ultimately undermine performance and longevity. Microstrain's inertial and wireless sensors allow for both vehicle inclination/angular position tracking as well as ongoing health monitoring. Inertial sensors are critical for angle sensing, vehicle position/incline monitoring and stabilization. Our wireless sensors enable monitoring critical vehicle component health to enable planned maintenance, maximize vehicle uptime, and reduce overall operation costs.

With Microstrain's integrated health monitoring systems, we can provide scalable solutions for tracking vehicle condition status without disrupting performance and operation. MicroStrain's feature-rich sensor designs deliver the reliability and accuracy needed to incorporate sophisticated inclination/angular position tracking and health monitoring capabilities into industrial/heavy-equipment/construction vehicles.

MicroStrain

Instant, comprehensive reporting of aircraft health, from nose to rudder

MicroStrain

MicroStrain’s distributed rotorcraft wireless health monitoring systems provide a wealth of information about aircraft component health and usage.

MicroStrain

Scalable solutions to track component use and vehicle health.

MicroStrain

Off-road vehicles such as bulldozers, excavators, and cranes are especially vulnerable to wear and misalignment. LORD MicroStrain® Sensing Systems provides embedded wireless solutions for monitoring track wear, structural loads, and more.

Equipment health monitoring and analysis enables predictive maintenance, reduces downtime, and reveals design improvement opportunities. Remote sensing and data collection saves labor, time, and improves safety.

D. O'Neil, C. Townsend; MicroStrain, C. Hodgkins, NAVAir Pax River

Effective and accurate torque monitoring has been, and will continue to be, an ongoing challenge in the industrial, agricultural, and aerospace arenas. Torque measurements are useful as an indicator of mechanical system health and desirable for test and p

MicroStrain

Sensors for Displacement Measuring

ZETA racing has one of only 4 multi-post shaker labs in the northern hemisphere. Their in-lab and on-track work depends on MicroStrain MV5-AR inertial sensors for data.

Parker Hannifin MicroStrain

Patented Near Field Communications and Power for Wireless Torque Monitoring

Parker Hannifin Microstrain

Joe Beckwith

Structural health monitoring (SHM) is critical for ensuring the safety and longevity of infrastructure, machinery, and equipment. HBK offers two innovative solutions that make SHM easy: HBK Weldable Strain Gauges and MicroStrain by HBK Wireless Technology

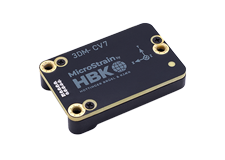

The GV7 series of inertial sensors offers improved performance and functionality over the GX5 series while maintaining the same compact size and easy-to-replace design. This upgrade is ideal for those seeking higher accuracy and additional features.